Description

Specifications of Portable Tunnel Dehydrator

| Output Capacity | 5000 kg |

| Tray Material | Steel/ Galvanized Steel |

| Overall Weight | 7800 kg |

| Body Material | Aluminum/ Steel/ Galvanized Steel |

| Dimensions | 260*1200*260 cm |

| Tray Dimensions | 60*80 cm |

| Total Racks | 18 trolleys: 648 trays/ 25 trolley: 900 trays |

| Furnace Material | Steel |

| Fuel Types | Gas |

| Three Phase | Yes |

| PLC Options | Can be requested |

| Capability | Works 24 hours |

| Guarantee | 12 Months |

| After Sales Services | 30 Months |

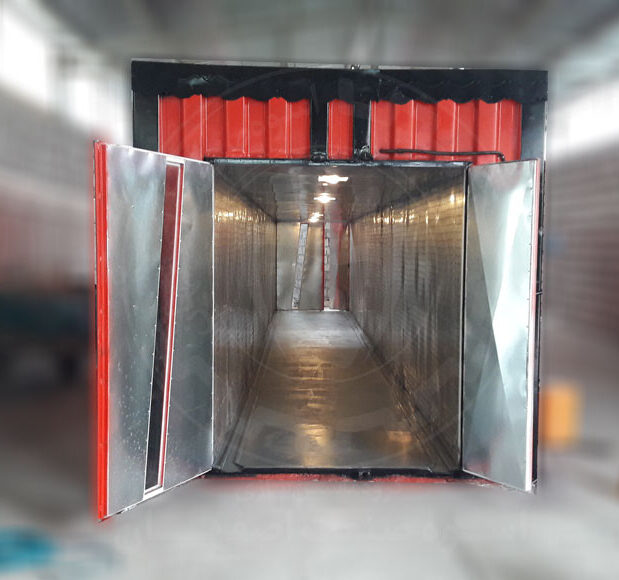

Insulation of Osveh Tunnel Type Dehydrator

The inner walls of the dehydrator are made of galvanized steel, while the outer walls are made of color coated galvanized steel, providing resistance against erosion.

The use of glass wool as insulation in some dehydrators is not recommended due to its tendency to distribute in the air and cause pollution. However, Osveh dehydrators use rock wool as thermal insulation, resulting in less energy consumption and no floating bits. Additionally, Osveh tunnel type dehydrators have double waterstop floors and four mounted sheets for easy movement. They also come equipped with an electrical control panel containing miniature keys and thermal relays to prevent motor burnout. Osveh dehydrators can dry a variety of items including food, medicines, chemicals, and minerals such as fruits, vegetables, roses, flowers, dairy products, meats, and pet food.

In certain dehydrators, glass wool is used as insulation between the walls. However, glass wool is not recommended for insulation due to its tendency to disperse in the air and cause pollution, which can be harmful when inhaled. On the other hand, Osveh dehydrator utilizes rock wool as thermal insulation between the walls, resulting in lower energy consumption and no airborne particles.

Osveh tunnel type dehydrators are equipped with double doors for easy access. The floor of the dehydrator is coated with two layers of paint: a standard paint and an erosion-resistant paint. This ensures that washing the dehydrator is hassle-free and problem-free. Additionally, there are 4 sheets mounted below the dehydrator to facilitate its movement.

Osveh Dehydrators Equipment

The Osveh Tunnel Type Dehydrator comes with an electrical control panel. Our 2-zone tunnel type dehydrator is equipped with a control panel that contains miniature keys. These keys are designed to trip when there is a weak connection or when the motor overheats. Furthermore, the control panel includes thermal relays that allow you to set a specific amperage based on the motor’s power. For example, if the motor has a power of 3 horsepower, it requires 15 amperes. If more than 15 amperes are supplied to the motor, it will automatically shut off, preventing any potential damage from overheating.

This dehydrator is equipped with 2 temperature controllers to accommodate its two burners. It also features a time and humidity controller for precise drying control.

What can be dried with Osveh Dehydrators? Osveh Dehydrators can dry a wide range of items including various types of food, medicines, chemicals, and minerals. Examples of items that can be dried include fruits and vegetables, roses and flowers, dairy products, meats, chicken feet, as well as meat and chicken by-products for dogs and cats.

What Makes Osveh Dehydrators Stand Out?

The Osveh Tunnel Type Dehydrator boasts several notable features. Firstly, each cabinet dehydrator is equipped with airflow dehydrators that ensure the even distribution of heat across every tray, resulting in a consistent temperature throughout.

Additionally, these dehydrators come with trolleys and shelves that can accommodate a varying number of trays, ranging from 10 to 184, depending on the size of the dehydrator. The tray materials are available in either galvanized or stainless steel options.

To further enhance efficiency, the dehydrators are fitted with three 80 g Automatic Iran Radiator Gas-fuel Burners, which not only provide reliable heat but also contribute to lower energy consumption.

Furthermore, these dehydrators are equipped with advanced technology such as PLC boards or Digital Shiva Amvaj Multi-timer, thermostat, and humidistat, ensuring precise control over the drying process.

For optimal circulation, the dehydrators feature six 1 hp centrifuges, while three 1 hp centrifugal vacuums effectively remove moisture from the system.

Lastly, the dehydrators are constructed with a double-walled design, incorporating thermal insulation made of mineral wool. This insulation helps maintain a stable internal temperature and improves overall energy efficiency.

Dehydrating Duration and Temperature

|

Time (hour) |

Product | Time (hour) | Product |

|

4 |

Dill, mint | 8 |

Sliced black figs |

|

6 |

chives | 13 |

Black figs |

| 4 | Tarragon, fenugreek | 14 |

Sliced lemons |

|

8 |

onion | 8 |

lemons |

|

8 |

garlic | 8 |

strawberry |

|

8 |

Persian shallot | 13 |

peach |

|

8 |

ginger | 13 |

Apricot |

|

5 |

mushroom | 13 |

plum |

|

15 |

melon | 13 |

Prunus domestica |

|

8 |

orange | 6 |

grapes |

|

8 |

banana | 18 |

Bunch of grapes |

|

8 |

tomato | 8 |

apple |

| 8 | pineapple | 8 |

kiwi |

| 8 | Sliced plums | 8 |

pear |

The dehydrating temperature must be between 55 to 70 degrees centigrade.

The times are according to the temperature and humidity parameters.

Reviews

There are no reviews yet.